Our Products

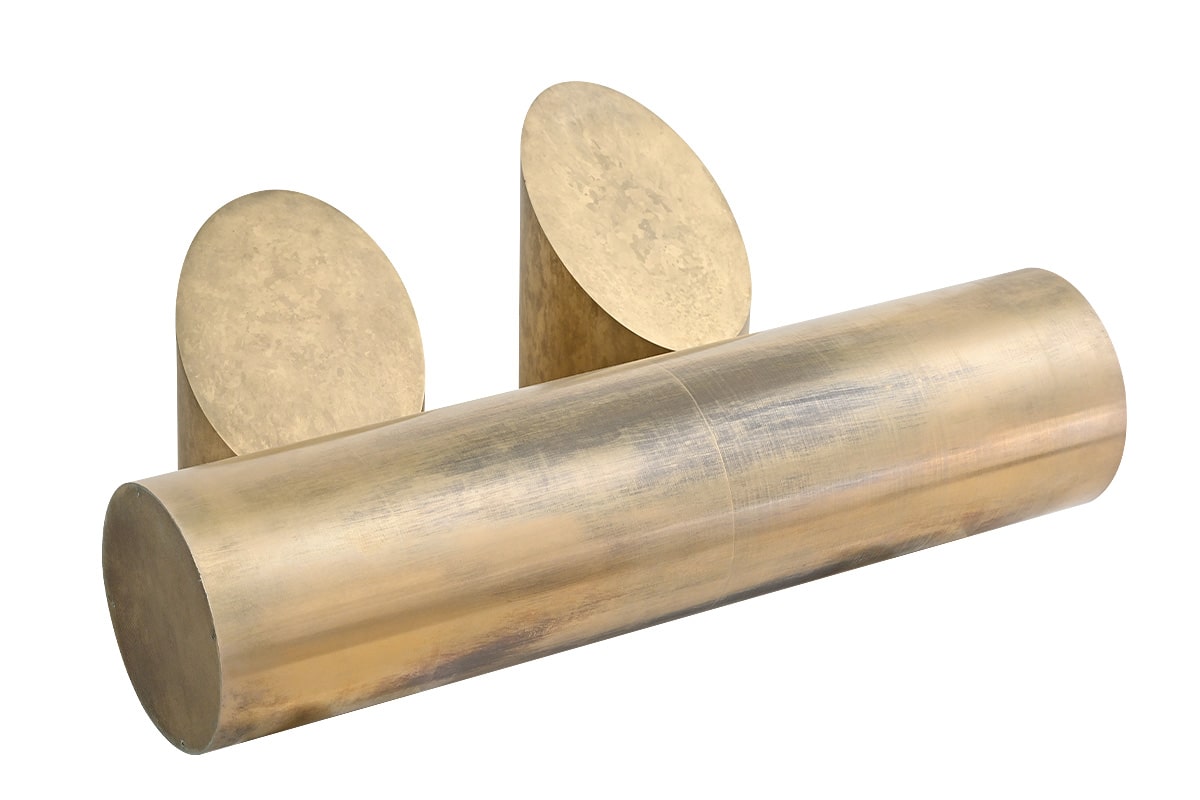

Ingots made via Mizuta

melt-solidification method

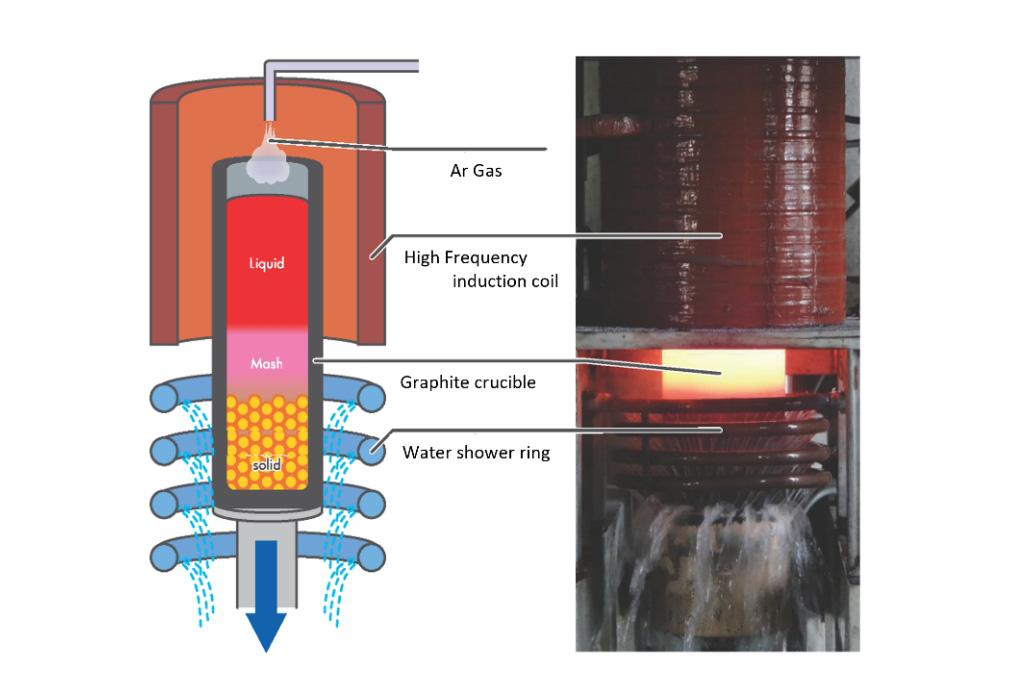

Mizuta melt-solidification method

Manufacturing method characteristics

- High-purity graphite electrodes are used in melting crucibles to limit contamination with impurities other than the materials.

- Materials can be melted down in a reducing atmosphere through heating in graphite crucibles.

- Molten metal never makes contact with the atmosphere since the process does not involve casting in molds, limiting oxidation.

- One-directional quenching is carried out by lowering crucibles filled with molten metal at a set pace in the water release process. This produces billets with uniform additive concentrations throughout the alloy, and minimal void formation.1)

- Crucible shapes and exchanges let us produce billets with distinct compositions in the 1 to 500 kg classes.

Proven Billet Production

The Osaka Alloying Works titanium-additive bronze billets of Niobium-tin (Nb3Sn) are used worldwide for superconducting cable materials.1,2,4,5)

These billets are thermal extrusion-molded, letting us produce container-sized billets for each extrusion machine.

Alloys that contain high vapor pressure elements (such as brass) have unstable compositions due to the intense vapor pressure when melted down in a vacuum. Control melting temperatures in the Mizuta method produces copper-zinc billets of stable compositions.4)

We produce billets using graphite crucibles for high-temperature processing of alloys that require high purity quality (5 to 6N).

We can produce alloys containing precious metals (such as gold, silver, and palladium) thanks to the high composition and weight yield rates of the process.

Billet Formats

See the table below for graphite crucible size (interior) and molten metal quantities (converted to copper).

*Other sizes also available with graphite crucible orders.

Inquiries welcome.

| No. | Diameter(mm) | Length(mm) | Conversion to molten copper(kg) |

|---|---|---|---|

| 1 | 60 | 220 | 4.3 |

| 2 | 60 | 240 | 4.8 |

| 3 | 85 | 210 | 8.1 |

| 4 | 110 | 255 | 17.5 |

| 5 | 100 | 350 | 21.1 |

| 6 | 125 | 280 | 25.3 |

| 7 | 120 | 450 | 40.5 |

| 8 | 165 | 820 | 147.5 |

| 9 | 182 | 1175 | 262.2 |

| 10 | 182 | 1235 | 276.2 |

| 11 | 240 | 1075 | 415.5 |

| 12 | 280 | 880 | 457.9 |

| 13 | 300 | 900 | 538.3 |

Mizuta melt-solidification method schematic and water quenching in progress3)

Nb3Sn superconducting bronze billet1)

References

- Hiroyasu Taniguchi, Akihiro Kikuchi: Low Temperature Engineering, Vol. 47 No. 8, pp. 526-533, 2012.

- Hiroyasu Taniguchi, Akihiro Kikuchi, Kozo Osamura, Taiji Mizuta: Low Temperature Engineering, Vol. 50, No. 4, pp. 186–193, 2015.

- Hiroyasu Taniguchi, Akihiro Kikuchi, Yasuyuki Miyazawa, Yasunari Mizuta, Taiji Mizuta: Copper and Copper Alloys, Vol. 60, No. 1, pp. 93-97, 2021.

- Hiroyasu Taniguchi, Akihiro Kikuchi, Yasuyuki Miyazawa, Yasunari Mizuta, Taiji Mizuta: Copper and Copper Alloys, Vol. 61, No. 1, pp. 92-96, 2022.

- Hiroyasu Taniguchi, Akihiro Kikuchi: “Novel High - Tin Bronze and Nb3Sn Multifilamentary Wires”, IEEE Transactions on Applied Superconductivity, Vol. 32, Issue: 6, DOI: 10.1109/TASC.2022.3163680, 2022.

CONTACT CONTACT CONTACT CONTACT

CONTACT CONTACT CONTACT CONTACT

We welcome your inquiry

See here for inquiries regarding products